Epoxy & Basin Restoration

Cooling Tower Basin Restoration & Leak Repair

Protocols reviewed by Ed Sawicki

(former Intel Corporate Safety Director).

Schedule a System Walk-Down

PAIN & SOLUTION

The ROI of Restoration vs. Replacement

Replacing a compromised cooling tower is a massive Capital Expenditure (CapEx) often exceeding $200,000 alongside crane lifts, downtime, and permitting.

The WSC Restoration Alternative: For a fraction of the replacement cost (typically 15-20%), we strip the basin down to the metal, remediate the rust, and seal it with a high-performance epoxy liner

Seals pinholes and seams.

Specialization

Our 4-Step Marine-Grade Process

Surface Prep:

We mechanically abrade the surface (sand/grind) to remove scale, biofilm, and existing rust.

Rust Remediation:

Application of industrial rust inhibitors to neutralize oxidation at the molecular level.

Patch & Fill:

Sealing of pitting, holes, and seams with high-strength filler.

Marine-Grade Epoxy:

Application of a heavy-duty, chemical-resistant coating designed for continuous underwater immersion.

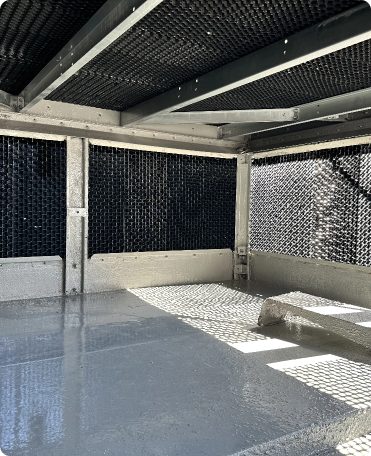

See the Transformation

Rusted, Leaking Basin (Risk of Failure)

Avoid the disruption of a full tower swap. Restore reliability in days, not weeks.

Before

Life Extended by 10+ Years to reinforce the CapEx deferral value.

After

Life Extended by 10+ Years to reinforce the CapEx deferral value.

Before

After

Life Extended by 10+ Years to reinforce the CapEx deferral value.

Before

After

Life Extended by 10+ Years to reinforce the CapEx deferral value.

Why Us

Why Bay Area Facilities Trust WSC

WSC is a mechanical expert, not a chemical company. We operate as a neutral “Switzerland”

Confined Space Safety: We refuse to cut corners on safety. All technicians are HAZWOPER 40 certified and follow strict entry logs.

Proper Curing Time: We manage the schedule to ensure the coating cures correctly before water refill, preventing premature failure.

No "Splash and Dash": We do the hard prep work that ensures the coating actually sticks.