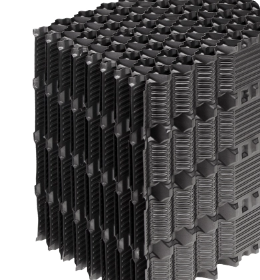

Fill & Drift Eliminator

Cooling Tower Fill & Drift Eliminator Replacement

ASHRAE 188 Compliance: Drift reduction strategies reviewed by Ed Sawicki

(former Intel Corporate Safety Director).

Schedule a System Walk-Down

HEART OF THE TOWER

Is Your Tower Suffocating?

The fill media is the heart of your cooling tower. If it is clogged with scale or biological growth, your heat transfer plummets, forcing your chillers to work harder and driving up energy costs.

We don’t just “wash” old fill. If the media is brittle or irreversibly fouled, we perform a surgical extraction and replacement, restoring the tower to its original design approach temperature.

Specialization

Complete Internals Restoration

Heat Transfer Fill (The Engine):

Installation of high-efficiency PVC fill packs (Cross-flow and Counter-flow)

Benefit: Maximizes surface area for water/air contact, instantly lowering supply water temps.

Drift Eliminators (The Safety Shield):

Retrofitting high-efficiency drift eliminators (0.001% drift rate).

Benefit: Critical for ASHRAE 188. Prevents aerosolized water (and potential Legionella) from escaping the tower and impacting the public/employees.

Air Intake Louvers (The Guard):

Replacement of broken or missing louvers.

Benefit: Keeps sunlight out (preventing algae growth) and keeps water inside the basin (stopping splash-out).

THE RETROFIT PROCESS

Turnkey Project Execution

Wrong packing kills efficiency. We don’t just dump in generic plastic. We source and install the exact media specification for your scrubber model:

Custom Sizing: We field-measure your tower to ensure exact fitment, preventing air bypass gaps that destroy efficiency

Materials Supply: Direct relationships with major media manufacturers (hanging sheets or bottom-supported blocks).

Disposal: We handle the removal and legal disposal of the old, fouled media.

THE ROI CASE

The ROI of Fill Replacement

Replacing your fill is a fraction of the cost of a new tower, but yields nearly identical performance gains.

Energy Savings: A 2°F improvement in approach temperature can reduce chiller energy consumption by ~5-6%.

Water Savings: New drift eliminators and louvers stop thousands of gallons of unnecessary water loss annually.

Schedule Fill Inspection

Are Your Approach Temps Rising?

If your tower can’t keep up with the load, your fill is likely compromised. Let us inspect the pack density and condition.